The Problem

Many existing residential buildings, such as apartment high rises, college dormitories, schools, etc., are equipped with two-pipe HVAC systems providing seasonal heating and chilling. Many of these are not equipped with any thermostats, so that residents have to regulate the temperature by cracking the window open. This is equally wasteful and uncomfortable.

Existing retrofit solutions fall broadly into two groups:

Line-voltage thermostats: low functionality (often not even basic scheduling); require code-compliant installation of power line from fan-coil unit to thermostat location, which often involves tearing walls open.

Specialized low-voltage thermostats with switchover capability: expensive; require complicated installation of several components, such as separately purchased transformers, relays, temperature sensors, and the specialized thermostat; non-standard and complicated wiring; not possible to install smarter thermostats as the need arises.

Unsurprisingly, market penetration of these retrofits is small, despite the obvious advantage in efficiency and comfort of going from no thermostat to a thermostat.

The Solution

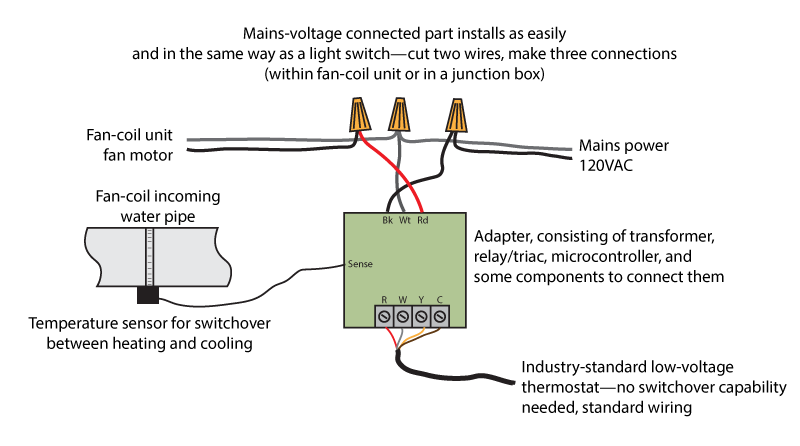

A premanufactured single-piece adapter connects on one side to the fan-coil unit and on the other side to any industry-standard low-voltage thermostat, which may be anything from a $10 bare-bones model to an attractive smart thermostat such as the Nest.

Installation on the line-voltage side is exactly the same as installing a light switch or dimmer—any electrician can do this very quickly.

Connection to the thermostat is standardized for low-voltage thermostats and easy. The thermostat cable is low-voltage and low-current and not subject to the safety rules for installing line-voltage wiring.

The adapter, not the thermostat, handles the heating/chilling switchover, enabling the use of standard thermostats not so equipped.

Solution is easiest, and prototypes have been working for years, for two-pipe fan-coil units with constant water flow, but the solution adapts to one- or four-pipe units and valve control.

The Business

Substantial economies of scale are achievable by retrofitting an entire building at once. Payback within one year is attainable.

Many of the potential customers (colleges, public housing, etc.) are publicly owned, and there are often substantial subsidies available, even to the point where the economic buyer doesn’t have to pay anything, but gets to keep all of the savings.

For private buyers, such as condo buildings, it might be attractive to offer installation for no upfront cost in return for a share of the energy savings achieved. Subsidies might be available for these buyers, too, though not as extensively as for public buyers.

Steps in going to market involve, beyond finding buyers, learning to work with all the disparate subsidy opportunities available, manufacturing the adapter in scale and in compliance with electrical codes in the majority of potential install locations (e.g., UL listing), learning to work with local contractors for the actual installation.

Extensions

The simplest instance of the solution as shown in the chart above is fire-and-forget. After it is installed, it just works without further interaction. Since the adapter’s behavior is defined in microcontroller software, it is easy to make custom versions for a site just by reprogramming the microcontroller.

In more advanced iterations, the adapter may be fitted with a cheap wireless mesh network module, enabling additional applications:

- Transmitting current state of each unit to the central HVAC system to allow nimble response to units coming on and off

- Separate billing for usage by unit (with a second temperature sensor), using constant or even dynamic pricing

- Unit-by-unit participation in demand-response incentive programs

Patents pending on some of the ideas disclosed here. For more information, contact Oliver M. Haynold at .